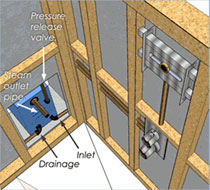

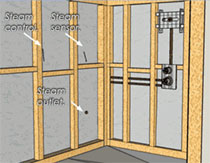

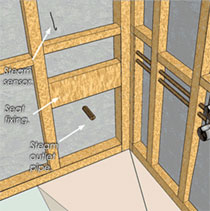

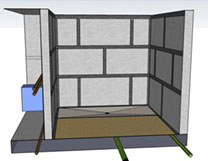

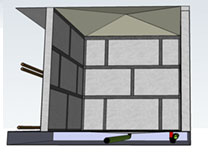

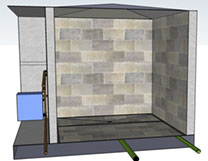

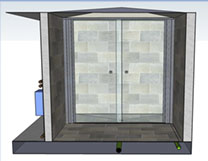

Diagram of Steam Room Fittings Layout

Fitting At A Glance | |

The 1-11 stages for the fitting of a steam / shower room | |

| |

A Steam Room in essence is a shower cubicle with a steam Below is a simplistic overview of the start to end of a | |

1) Construct any timber / metal studwork / masonry wall that may be required. 2) Install and plumb shower tray or wet room tanked floor. 3) Plumb in shower controls, showerhead and water supply to steam generator plus pipe work for steam outlet. 4) Position wiring for steam temperature sensor and lighting and steam room digital control (which is to be outside of steam shower area) 5) Construct secure fixing for steam room seat (if required) 6) Install insulated tanking boards to wall area. 7) Construct sloping ceiling. 8) Install wall tile or wall covering chosen. 9) Install cubicle or shower door. 10) Fix shower control, steam outlet, shower head and digital control. 11) Connect steam generator to water and electrical supply. |

| |||||||||||||||||||||||